24??media Can Be Fun For Anyone

24??media Can Be Fun For Anyone

Blog Article

5 Easy Facts About 24??media Described

Table of ContentsWhat Does 24??media Do?The Basic Principles Of 24??media 24??media Can Be Fun For AnyoneExcitement About 24??mediaThe Definitive Guide for 24??media

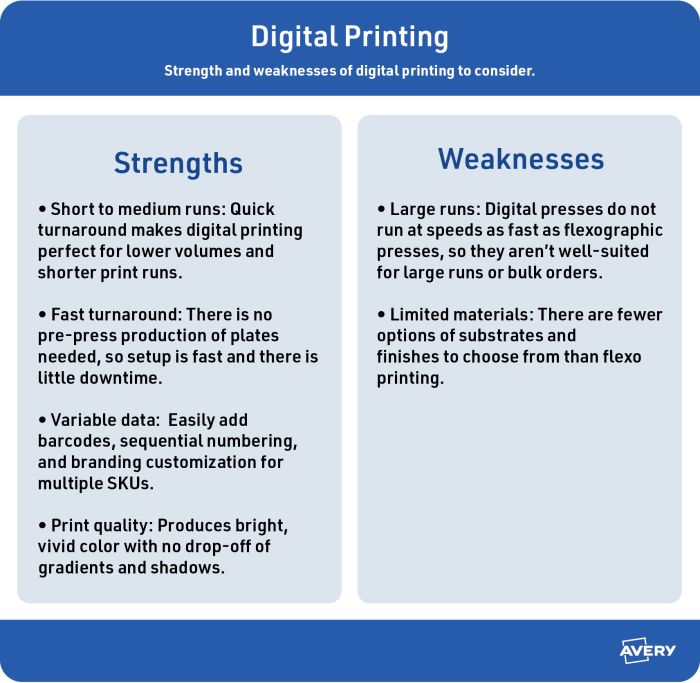

Innovations in print innovation are changing the interactions playing area when it concerns high quality, cost and sophisticated capacities. Offset printing and electronic printing are the significant processes whereby print jobs are carried out both making use of four-color printing techniques. Each choice has its benefits, providing different strategies to meet the demands of diverse manufacturing jobs.

Usually, this has actually been one of the most consistent strategy for precisely keeping color matches, making it ideal for print runs that only need static printing such as pre-printed types, brochures, leaflets, calling card, and bulk postcard mailings. Nevertheless, as a result of the static nature of litho printing, it is not perfect for variable print pieces that will certainly be sent by mail to individual recipients such as statements, letters, and personalized postcards.

8 Simple Techniques For 24??media

The latest advancements in print modern technology are assisting to bring most of offset's advantages into the electronic printing world genuinely altering the face of modern printing! There are some key distinctions between Offset Printing and Digital Printing (Wallpaper). This guide reveals the advantages and drawbacks of each printing approach. There is an obvious and growing number of benefits to using the digital print procedure.

Today's digital print equipment is amongst one of the most advanced on the market. Here are several of the greatest benefits of using electronic printing: dominate the digital print room, with full-color printing completed in one procedure and perfectly published directly from a print data. Without a prolonged set up process, the calibration time of a certain job is shortened, adding to quicker print time and general shipment.

The inkjet printing process has actually assisted to change the market in addition to the quality and speed of the result. The most recent inkjet modern technology can publish on conventional offset stocks with plain, silk, and glossy coatings. High-grade electronic print coupled with software-managed shade monitoring practices adds optimum worth to print items and makes production processes a lot more trustworthy than balanced out.

Excitement About 24??media

(https://www.ted.com/profiles/48812580)

Specific amounts of ink and printer toner are utilized to stay clear of waste. Eco-friendly and biodegradable inks and toners are also offered for more sustainable printing. Digital print likewise removes the demand to wash plates or coverings with harmful chemicals at the end of the printing procedure. As the high quality of electronic print solutions raises, the benefits end up being significantly noticeable and helpful.

Variable information helps services reach their specific clients and audience with uniquely-created and individualized web content. As modern technology improves, the top quality of electronic printing has come to be second-to-none, with better detail, color match capacities and total accuracy. Without the need to clean plates or utilize excess ink, digital printing is likewise much less wasteful and typically much more ecologically friendly.

("flexo"), entail several make-ready steps to transfer an original image to a substrate.

Some Known Questions About 24??media.

Digital printing, with less moving pieces, is extra dexterous than offset in this respect.

It's a method to mix your product packaging and advertising techniques. Reduced set-up time conserves cash on the front end. And considering that these are not large mass orders, smaller organizations can afford to print without needing to satisfy the greater and a lot more expensive print thresholds of typical printing. Digital printing aids protect your brand versus counterfeiting by including obvious and covert services on your product packaging.

Be sure you team up with a printing and packaging companion who has the right qualifications. While eleventh-hour printing and modification are a massive benefit, digital might not constantly be the most effective method for you. Offset printing has the advantage of cost-effectiveness with big print runs, find out especially those with sophisticated attractive results and specialized finishes.

Getting My 24??media To Work

Lithographic presses use 2 print platesa positive and a negativeto transfer top quality shade graphics onto a suitable substrate. The positive plate, with its smooth surface, attracts oil-based inks and drives away water. In comparison, the unfavorable plate, with its rough texture, soaks up water and fends off oil. Rubber rollers are then utilized to transfer the image from home plate to the corrugated surface area.

Corrugated paper can often show to be a challenging surface to publish on, yet Litho prints to a different surface and is after that laminated flooring to it, making it very easy to print top quality photos. It can be exceptionally constant, also for long runs. The more you print, the more affordable the prices become for Litho.

What Litho does not provide you is precisely what Digital does, modification. Costly set up Longer turnaround No Variable Data Printing Smaller sized color gamut, shades can be much less brilliant Digital printing is the procedure of printing digital images straight onto the corrugated substrate using a single-pass, direct-to-corrugate method.

Report this page